Engineering Support & Customer Service

PCB Design Support for Prototyping and Production

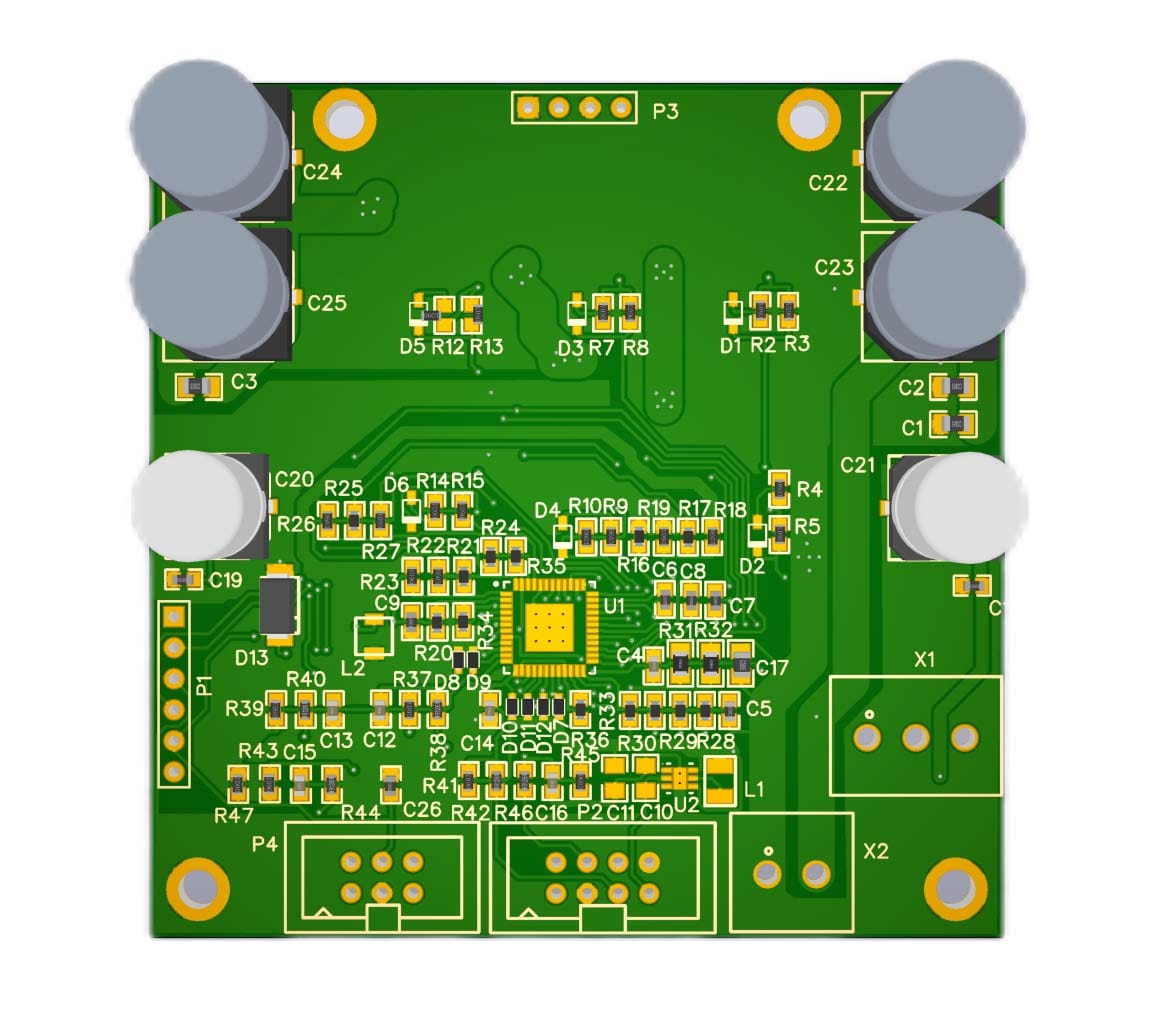

Our PCB Design Capabilities Include:

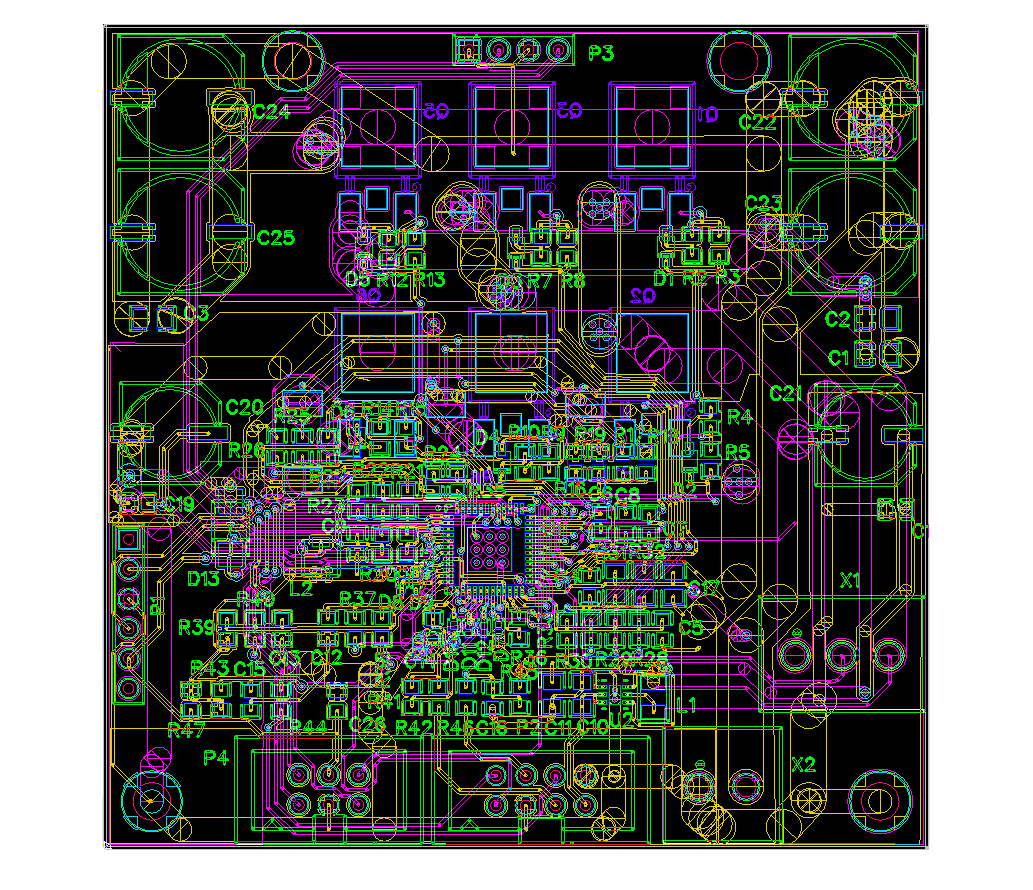

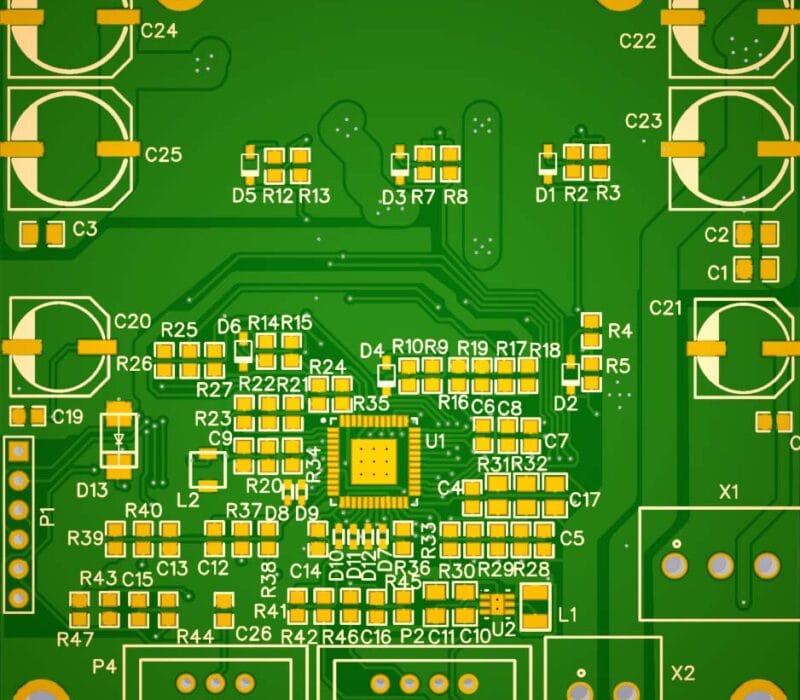

Custom PCB Layout Design

Single-sided, double-sided, and multilayer PCB, including HDl and high-speed PCB designs.

Expert PCB Schematics

Circuit board schematics, ensuring electrical performance and signal integrity from the earliest designphase.

PCBA Firmware Development

Custom PCBA software development—firmware & embedded programming services.

Design for Manufacturability (DFM)

Free PCB DFM, optimize PCB layouts for smooth, cost-effective fabrication and assembly.

Design for Testability (DFT)

Implementing test points and strategies to simplify inspection and troubleshooting.

High-Speed & RF PCB Design

Expertise in impedance control, signal integrity, and noise reduction forcomplex applications.

Why Choose Us for PCB Design?

One-Stop Service

From PCB design to manufacturing and assembly.

Experienced Engineering Team

More than 15 years of industry expertise.

Fast Turnaround Times

Fast PCB prototyping and streamlined design workflows.

Certified Quality

ISO9001, IATF16949, RoHS and UL compliant.

Custom Solutions

Custom PCBA Solutions for your industry needs.

Reduce Manufacturing Risk

Smooth transition to producton.

FAQs

PCB layout design is the process of placing and routing components on a printed circuit board to ensure the electrical functionality, manufacturability, and performance of the board. It bridges the gap between a schematic and a physical PCB.

PCB firmware development involves writing and programming the embedded software that runs on a printed circuit board assembly (PCBA). It allows the hardware to perform specific tasks, interact with other devices, and operate reliably in real-world applications.

Design for Manufacturability (DFM) ensures your PCB design is optimized for easy and cost-efficient manufacturing. By identifying potential production issues early, DFM reduces delays, minimizes rework, and helps your design transition smoothly from concept to final product.

Leverage industry-leading software like Altium Designer, Eagle, KiCad, and OrCAD for creating professional PCB layouts. These tools offer powerful features for schematic capture, layout design, and simulation to streamline your PCB design process.

Industries We Serve

Medical Devices

Medical Devices

Energy

Medical Devices

Medical Devices

Comsumer Electronics

AIoT Products